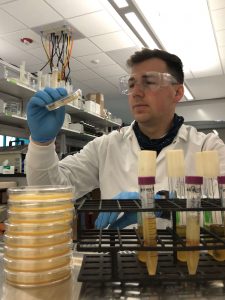

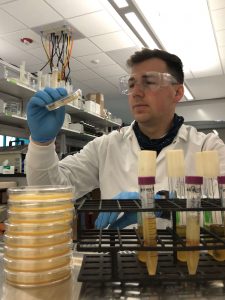

Dr. Josh Cassar has been researching Pulsed Light’s application in food safety for years, with one project in particular receiving a significant amount of attention: Pulsed Light processing of chicken eggs.

Dr. Cassar earned his PhD at Penn State, and there has received international attention. His study of chicken eggs found that Pulsed Light is an effective alternative to the traditional antimicrobial technology used in the poultry industry. His research has been picked up by industry publications around the world.

Why all of the buzz about chicken eggs? The fact is that around 9% of all foodborne illnesses in the U.S. are associated with eggs. According to CDC data, there are 9.4 million lab-confirmed cases of foodborne illness every year. Their own review of the estimate states that “there is always room for improvement.” Dr. Cassar’s research is an important step forward in food safety.

These days, Dr. Cassar is a food safety consultant for HACCP Assurance Services in Pennsylvania. I recently had the opportunity to ask him some questions about his work with Pulsed Light.

Q: Why did you choose to study chicken eggs?

A: This project was a portion of my graduate work at Penn State investigating the use of Pulsed Light for decontamination of meat and poultry products. I had also researched the applicability of Pulsed Light for pet foods and food-contact conveyor surfaces. Of all the research we’ve published, this particular project has gained the most traction. Penn State did a press release about it and it was picked up all over the world. The reaction has been a pleasant surprise.

Q: What were your findings?

A: We observed a significant microbial reduction on the surface of eggs without compromising quality. Pulsed Light achieved up to a 5-log (99.999%) reduction, and this is with cumulative treatment that falls within 12.0 Joules per-square-centimeter allowed by the FDA (Code 21 CRF 179.41). Also, to our surprise, when evaluating the treatment of fertile hatching eggs, there were no effects on egg hatchability and chick livability That means the technology can be used beyond eggs intended for consumption but also include eggs intended for hatching.

Pulsed Light is pertinent not just to food safety, but also to animal rearing, by reducing adverse microorganisms that would otherwise infect chicks. The same systems that we used for consumer eggs can be implemented in hatcheries for treat hatching eggs. There are quite a few ways that Pulsed Light can be applied in food safety and food processing spaces.

Q: Why is it so effective with eggs?

A: Pulsed Light works best on smooth surfaces, and of course eggs are simple in structure. The only hurdle was completely rotating the eggs to ensure that the entire surface would be exposed to the Pulsed Light; so we developed a specialized conveyor to rotate the eggs completely.

A: We observed a significant microbial reduction on the surface of eggs without compromising quality. Pulsed Light achieved up to a 5-log (99.999%) reduction, and this is with cumulative treatment that falls within 12.0 Joules per-square-centimeter allowed by the FDA (Code 21 CRF 179.41). Also, to our surprise, when evaluating the treatment of fertile hatching eggs, there were no effects on egg hatchability and chick livability That means the technology can be used beyond eggs intended for consumption but also include eggs intended for hatching.

Pulsed Light is pertinent not just to food safety, but also to animal rearing, by reducing adverse microorganisms that would otherwise infect chicks. The same systems that we used for consumer eggs can be implemented in hatcheries for treat hatching eggs. There are quite a few ways that Pulsed Light can be applied in food safety and food processing spaces.

Q: Why is it so effective with eggs?

A: Pulsed Light works best on smooth surfaces, and of course eggs are simple in structure. The only hurdle was completely rotating the eggs to ensure that the entire surface would be exposed to the Pulsed Light; so we developed a specialized conveyor to rotate the eggs completely. Pulsed Light is an antimicrobial intervention that any egg processing facility could easily incorporate into their process. In some cases, egg processors use continuous, low energy UV systems that can take up a large amount of space. Pulsed Light could achieve the same or greater microbial reduction in a much smaller footprint than monochromatic UV light.

I don’t see any reason why Pulsed Light couldn’t be applied in egg processing facilities and hatcheries across the country, as part of a hurdle approach or as an independent antimicrobial intervention.

Q: Are there other applications researchers should be investigating?

A: Absolutely. Pulsed Light is unique in its application for food processing, in that it is nonthermal, nonaqueous, nonionizing, and nonchemical, and results in a significant microbial reduction. It can be a very valuable intervention for the food industry.

The technology is easy to work with. We used XENON systems that were very simple to set up and operate. Safety issues are important when you’re dealing with Pulsed Light, but the devices made it easy to manage. At the same time, it’s important to remember that every application has pros and cons. Pulsed Light is not the magic answer to all food safety problems, but with careful research and experimentation, there is huge potential for Pulsed Light to be incorporated in food processing settings.

Q: What is your main message to researchers?

A: As with all current and novel antimicrobial interventions used in food processing, there are opportunities to continue to research and optimize Pulsed Light’s applicability. There are ideal applications out there waiting to be explored. With its unique characteristics, Pulsed Light is an incredibly powerful resource when it is used in the right place and the right way. I encourage researchers to continue to study this technology and identify additional applications.

_______

Thanks to Dr. Joshua Cassar for taking the time to give this interview. Research was conducted by Dr. Cassar and his team (Dr. Edward Mills, Dr. Ali Demirci, Dr. Jonathan Campbell, and Dr. Paul Patterson) at the Pennsylvania State University. Led by researchers like Dr. Cassar, Pulsed Light is poised to change the food processing industry and keep consumers safer. If you have research ideas for Pulsed Light that you’d like to explore, please contact XENON. Our scientists and engineers are ready to help you discover the next perfect application for Pulsed Light.

Pulsed Light is an antimicrobial intervention that any egg processing facility could easily incorporate into their process. In some cases, egg processors use continuous, low energy UV systems that can take up a large amount of space. Pulsed Light could achieve the same or greater microbial reduction in a much smaller footprint than monochromatic UV light.

I don’t see any reason why Pulsed Light couldn’t be applied in egg processing facilities and hatcheries across the country, as part of a hurdle approach or as an independent antimicrobial intervention.

Q: Are there other applications researchers should be investigating?

A: Absolutely. Pulsed Light is unique in its application for food processing, in that it is nonthermal, nonaqueous, nonionizing, and nonchemical, and results in a significant microbial reduction. It can be a very valuable intervention for the food industry.

The technology is easy to work with. We used XENON systems that were very simple to set up and operate. Safety issues are important when you’re dealing with Pulsed Light, but the devices made it easy to manage. At the same time, it’s important to remember that every application has pros and cons. Pulsed Light is not the magic answer to all food safety problems, but with careful research and experimentation, there is huge potential for Pulsed Light to be incorporated in food processing settings.

Q: What is your main message to researchers?

A: As with all current and novel antimicrobial interventions used in food processing, there are opportunities to continue to research and optimize Pulsed Light’s applicability. There are ideal applications out there waiting to be explored. With its unique characteristics, Pulsed Light is an incredibly powerful resource when it is used in the right place and the right way. I encourage researchers to continue to study this technology and identify additional applications.

_______

Thanks to Dr. Joshua Cassar for taking the time to give this interview. Research was conducted by Dr. Cassar and his team (Dr. Edward Mills, Dr. Ali Demirci, Dr. Jonathan Campbell, and Dr. Paul Patterson) at the Pennsylvania State University. Led by researchers like Dr. Cassar, Pulsed Light is poised to change the food processing industry and keep consumers safer. If you have research ideas for Pulsed Light that you’d like to explore, please contact XENON. Our scientists and engineers are ready to help you discover the next perfect application for Pulsed Light.

Dr. Cassar achieved up to a 5-log (99.999%) reduction in contaminates using Pulsed Light.

Dr. Cassar’s team developed a conveyor to handle the eggs, enabling 360 degrees of exposure to Pulsed Light.