A few years ago in this space, we described Pulsed Light as the “Duct Tape of technology” because it’s so extremely versatile. If anything, that may have been an understatement, because new applications keep turning up.

From food packaging to solar cells, from printed electronics to mushroom farming, Pulsed Light is having an impact. How can one technology be so useful to so many unrelated industries?

The answer is, each application takes advantage of a different characteristic of Pulsed Light.

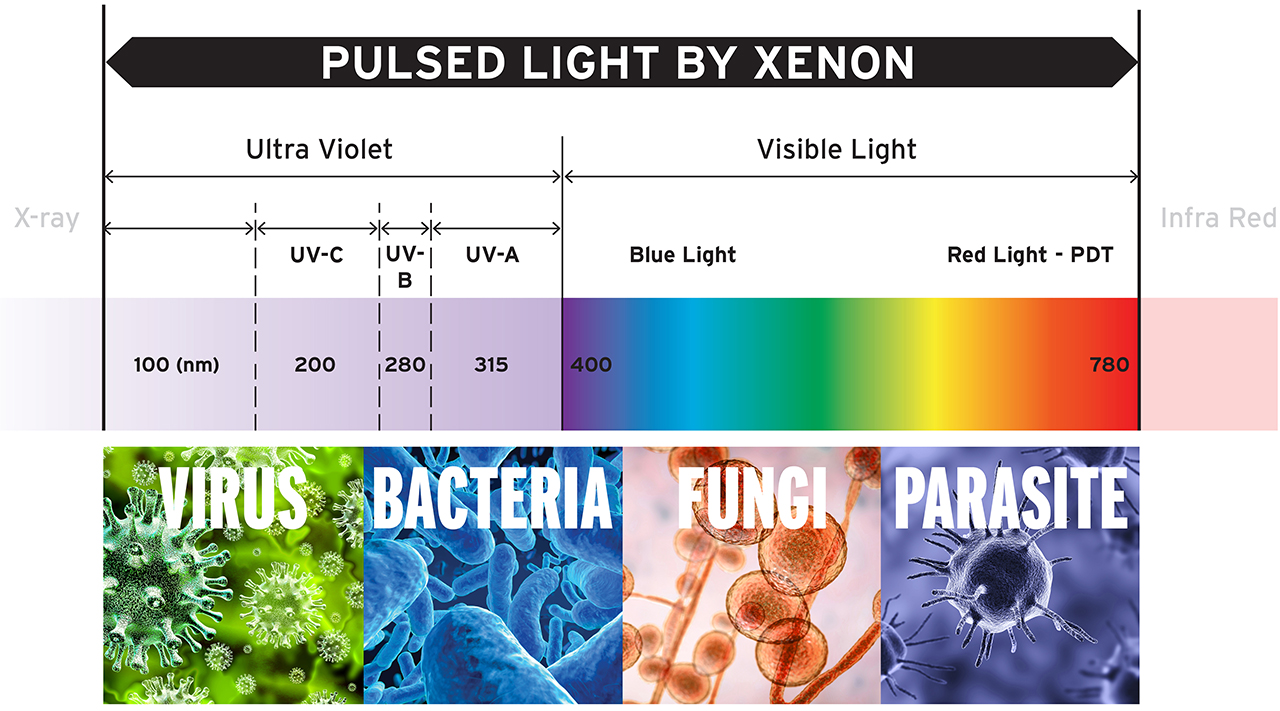

For some applications, it’s the ability of Pulsed Light to generate the full color spectrum of light, like the sun, while other applications take advantage of specific pathogen-killing frequencies. For some, it’s the high energy that Pulsed Light produces. And for others, it’s the low heat. And finally, for some applications, it’s all of those things.

Let’s take a closer look at how Pulsed Light brings different qualities to each application—and why it might be the solution you’ve been looking for.

The Color of Light

As you may remember from school science class, a beam of light aimed at a prism reveals that light is actually comprised of all the colors in the rainbow, otherwise known as the full spectrum.

Pulsed Light has the remarkable ability to produce the full spectrum of sunlight, from ultra violet to infra red. This makes it an ideal technology when the simulation of sunlight is required, such as in solar cell testing.

But many applications require only certain colors within the spectrum, and this is where Pulsed Light really shines. Whatever frequency is needed, Pulsed Light can produce it.

Take mushrooms, for example. Edible mushrooms contain very little vitamin D, as most are grown in the dark. However, mushrooms are rich in ergosterol, a precursor to vitamin D, and this can be activated by exposure to specific ultraviolet (UV) light frequencies. Treatment of mushrooms with Pulsed UV Light converts the ergosterol into vitamin D, resulting in a food source that contains 100% of the recommended daily allowance of vitamin D.

As a pathogen-killer, Pulsed Light is unrivaled. Virus and bacteria are vulnerable to specific frequencies of UV light while fungi and parasites are destroyed by frequencies of light within the visible spectrum. Pulsed Light can produce all of those frequencies, and it’s the only technology that can do it.

In food packaging, Pulsed UV Light is used to sterilize the package prior to filling to improve safety and extend shelf life. Food conveyors, floors and HVAC systems are other popular uses in the food production industry. Volumes of research have shown that many food surfaces themselves can also be decontaminated with Pulsed UV Light.

Beyond the food industry, systems have been developed to decontaminate everything from airport security bins to hospital rooms. Pulsed UV Light was a key weapon in the battle against Covid 19.

The Power of Light

The efficacy of Pulsed Light is not only in its color, but in the incredible power that it generates.

Pulsed Light generates intense bursts of energy, often reaching peak power levels in the range of kilowatts or even megawatts. As a result, it can cure materials much faster than other methods, often reducing the process from hours to mere seconds.

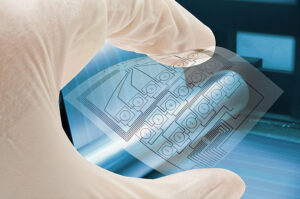

Exposing metallic inks to high-energy Pulsed Light turns them into conductive circuits, which makes it possible to produce printed circuits onto flexible substrates like cloth, plastic, and even paper.

With Pulsed Light, curing can take place at production speeds, so it can pay for itself in throughput alone. Applications include the curing of Blu-Ray DVDs, as well as the sintering of metallic inks used in printed electronics. Pulsed Light’s high energies also accelerate many of the applications mentioned above, increasing their efficiency and cost-effectiveness.

Yet despite its high-energy output, Pulsed Light produces minimal heat. That’s because it generates energy in rapid bursts, typically only a second or two, before the target object has time to heat up. Thus, Pulsed Light can be used in applications with sensitive materials like plastics, paper, and even food itself.

Researchers at Penn State University developed a customized conveyor to turn eggs to enable full exposure to Pulsed Light.

In some cases, low heat is a critical advantage that Pulsed Light brings to the application. It’s what allows printed electronics to be used with virtually any material at production speeds. It’s why mushrooms can be vitamin D-enhanced without accidentally burning or cooking them. Not every application is concerned with heating, but many are. In those cases, Pulsed Light may be the only available solution.

Yes, even chicken eggs

As a mark of just how versatile Pulsed Light is, we’ll leave you with this. A research team at Penn State University found that it can be used to decontaminate the outside of chicken eggs. Using a modified conveyor that turned the eggs, the researchers showed that the full surface of eggs can be exposed to Pulsed Light during processing, sterilizing the outside while leaving the inside of the egg unaffected. It’s a breakthrough in egg safety that could save lives, and you can read more about it here.

Powered by XENON Pure Pulse Technology

This blog has covered a lot of industries, and all these applications are powered by XENON Pure Pulse™ Technology. From enhancing the nutritional value of foods and optimizing solar cell performance to eradicating pathogens and expediting curing processes, XENON Pure Pulse Technology offers efficient and effective solutions.

If you’d like to investigate Pulsed Light for your application, XENON offers special research systems to get started as well as a wide range of flash lamps and supporting systems when you’re ready to go into production. Pulsed Light is the technology of choice for solving challenging problems. Bring your “project impossible” to XENON, and we’ll help you find a solution.

Contact XENON today to learn more.