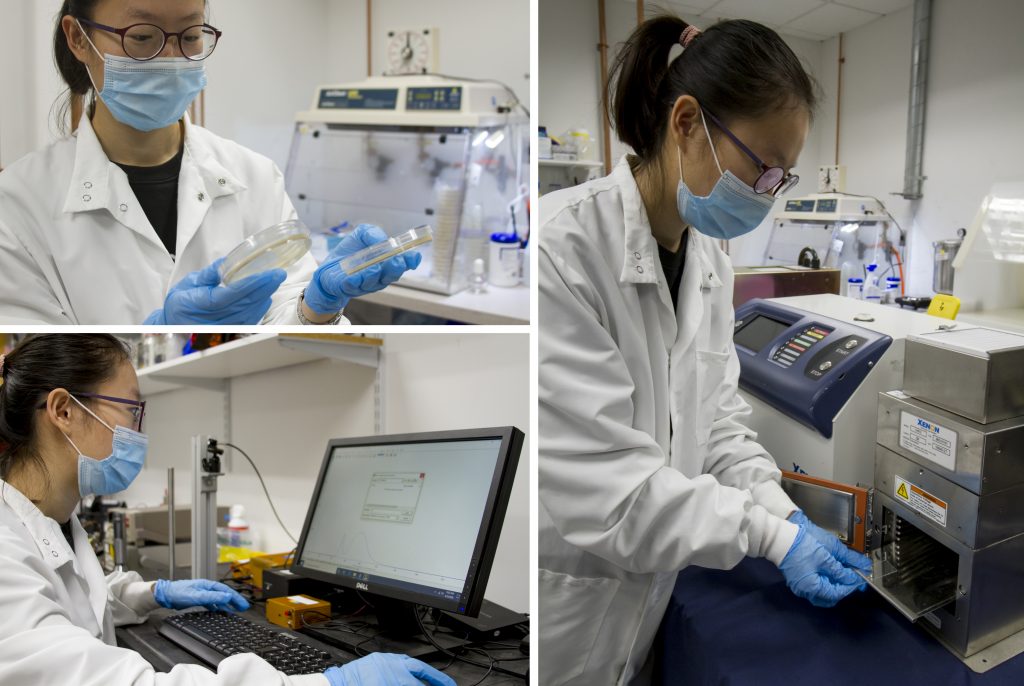

As part of this effort, XENON has created its own in-house microbiology lab. Headed by microbiologist Beining Ouyang, the lab is equipped with all the tools required to develop test protocols for customers’ biological challenges as well as to conduct research on the decontamination effect of Pulsed Light for various applications. Beining’s laboratory is able to perform a full range of activities for XENON customers, including onsite and offsite testing and validation.

Beining Ouyang, Microbiologist, XENON Corp.

Beining completed her MS degree in Agricultural and Biological Engineering at Penn State University, where she wrote her thesis on how Pulsed Light inactivates bacteria like E. coli and salmonella.

Recently, I had the opportunity to ask her about the laboratory, her research, and how she works with customers to develop new applications.

Q: How did you become interested in the subject?

Beining: “My master thesis was about Pulsed Light. I attended Penn State University in the Agricultural and Biological Engineering department, where I did my research on the effectiveness of Pulsed Light on pathogens in food. Working with my professor, Dr. Ali Demirci, we were interested in how Pulsed Light affects Salmonella in eggs. This method is relatively new. It’s not the traditional way. People usually use heat or continuous UV light. In the future, I think more people will be interested in Pulsed Light technology because of its effectiveness and unique capabilities.”

Q: How would you describe your role at XENON?

Beining: “My responsibility has two parts: microbiology testing and engineering. In pre-sales, I help potential customers test how effective Pulsed Light will be for their application. For example, if a customer wants a 3-log reduction in pathogens (99.9% bacteria inactivated), I will develop testing methods for their application. They provide samples for me to perform the testing, and I find the shortest time and optimal conditions to meet their goal. Then, I help them do their verification, anything from designing to installing a device. They still need to verify on-site since there are so many variables in the real world. If they don’t have their own microbiologist, I can provide guidance and advice.”

“I also do fundamental research and experiments regularly, compiling germicidal efficacy data on different surfaces by Pulsed Light.”

Beining develops test protocols for customers’ biological challenges and conducts research on the decontamination effects of Pulsed Light for a variety of applications.

Q: Do you share your data with customers and prospects?

Beining: “I organize and summarize so that we have a microbiology efficacy data sheet, which I have published. Many customers benefit from my data, because it’s not always application-specific. For example, how do certain distances and pulse times create different log reductions on hard surfaces? This can be applied to many things. If we want a table top sterilized, for example, I can use this data as a starting point, and I will share that with the customer.

“Not all research is around sterilization. I also study food enhancement. Recently, I did a test on mushroom powder, which is used in supplements and spices, where we found Pulsed Light produced a great increase in Vitamin D.”

Q: Can you describe your laboratory?

Beining: “Here at XENON, we have a Biosafety Level 1 laboratory, so we are restricted to non-pathogen bacteria. This is the same level that our customers have. For our testing, we usually use Bacillus pumilus as a biological Indicator. This bacterium is highly resistant to UV light. It’s a good biological challenge for monitoring radiation sterilization processes, and it’s widely used in labs as a surrogate for actual pathogens. Based on different applications and requirements, sometimes we are required to get 3-log or 4-log reduction (99.9% or 99.99%) using the Bacillus pumilus.”

Q: When evaluating the effectiveness of a Pulsed Light application, how do you measure it and confirm that it’s working?

Beining: “Let’s take an example. Say we’re testing a certain container to find whether we can achieve a 2-log or 3-log reduction. I’ll meet with the engineer and the customer to understand their processing line, and how they will incorporate the Pulsed Light unit. Will they need the lamp to be linear, spiral, or U-shaped? Once we choose the lamp and system, I will design a microbiological experiment for proof of concept. I artificially inoculate the B.pumilus, place it on the test object, and perform Pulsed Light tests with different distances and exposure times. After the test, I will incubate the sample for 3 days. If the bacteria do not grow, then the Pulsed Light application is proven effective.”

Q: Is your service included when customers purchase XENON equipment, or is it an added service?

Beining: “It depends. Sometimes if we can use the data I have already accumulated as a reference, it can be at no cost to the customer. My guidance during meetings is part of what XENON offers. Sometimes I need to spend a couple of days on one project. If it’s a new kind of object that needs to be sterilized, then we have to test an array of distances and pulses and incubate each setting, so I’ll have to perform many different tests. That’s an optional service for customers.”

Q: How has it been working with customers online instead of face-to-face?

Beining: “Lately, we meet with customers online instead of working face-to-face. Before the pandemic, customers usually came to the lab with samples and we designed the testing together. However, now we collaborate remotely. But it has worked out well. They ship the sample for me to work on, and if I have a question, I just call. Our lab is still fully able to work with customers and provide all our services despite the lockdown.”

———————————————————–

There is still much more to discover about Pulsed Light. We are seeing new, innovative ways this technology can protect us from pathogens and food-borne illnesses — whether it’s the novel coronavirus, E. coli, or a new problem we will face in the future. With XENON’s microbiology lab, guided by Beining’s research and testing expertise, customers have the support they need to continue pioneering new solutions to keep us safe.

We’ll keep you updated as Beining continues her discoveries of Pulsed Light technology.