Despite the best efforts of industry and government, foodborne illnesses continue to be a public safety issue, as this long list of outbreaks in the U.S. shows. The 2020 E. coli outbreak, to take one example, was linked to leafy greens that sickened people across 29 states.

Now the Food & Drug Administration is calling for the entire industry to find new technologies and approaches at every stage of food safety. In the latest guidelines for 2023 in the Food Safety Modernization Act (FSMA), the FDA’s goal is to shift the culture of food safety from responding to outbreaks after they happen to preventing them in the first place.

Of course, food processors know the importance of food safety and often use a hurdle approach to protecting food by having multiple lines of defense against pathogens and contaminants.

But there’s one area in particular where new solutions are badly needed, and that’s aseptic food packaging.

Why food packaging?

Like food itself, food packaging is vulnerable to contamination from many sources and can provide favorable conditions for microorganisms to grow. Aseptic packaging is the process of sterilizing food packaging separately from the product and then sealing it under sterile conditions as quickly as possible.

For decades now, food packagers have been using the same aseptic techniques. These include:

- Chemical treatment: Chemicals are effective at eliminating bacteria, but they can be dangerous and difficult substances to manage. There are many health risks (to both workers and consumers) involved with liquid and gaseous chemical treatments.

- Heat treatment: Heat can be applied in many ways to sterilize packaging, often in combination with chemicals. But different packaging and food items have different sensitivities to heat treatment, limiting its usefulness.

- Protective packaging: Aside from heat and chemical treatments, the packaging itself can protect the product with vacuum-sealing or modified atmosphere packaging. Removing oxygen from inside the packaging prevents the growth of microorganisms, but it can also dull the flavor and appearance of the food inside.

While effective to varying degrees, all of these approaches have limitations. Now Pulsed Light is emerging as an important new alternative.

Why Pulsed Light is so effective

Pulsed Light offers the advantages of other aseptic treatments, but without the disadvantages or limitations. It is non-chemical and non-thermal. It only needs seconds to work and does not use a mercury source or LED’s.

Since Pulsed Light generates no heat, it can work with any kind of packaging material. And, it’s approved by the FDA for use with food, so it can be used with confidence at any stage of food processing.

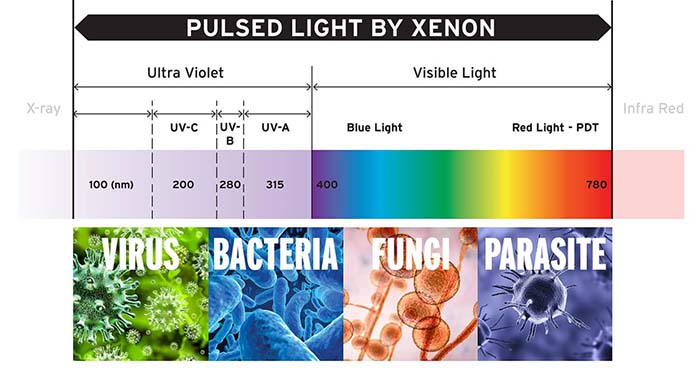

Most importantly, Pulsed Light is unmatched at deactivating or killing every kind of pathogen, including virus, bacteria, mold, and fungus, in part by overwhelming the DNA repair mechanism. This has been well proven for some time, and researchers at Cornell have been looking specifically at Pulsed Light in food packaging. The results are exciting and clearly demonstrate that Pulsed Light is a viable and effective approach to aseptic packaging. (You can read more about Cornell’s research here.)

Why XENON PurePulse technology is the right choice

To be effective in food safety, a Pulsed Light solution must deliver consistent, repeatable performance from the power supplies, lamps, and every electrooptical component in the system. It’s a technology that requires high energies and precision operation.

This is why XENON PurePulse technology for sterilizing and disinfecting is the ideal solution for aseptic food packaging. It has been tested and refined over many years, and proven in hundreds of applications. We manufacture the lamps in our own facilities to ensure the perfect design for the application, exceptionally high quality and consistent operation. Last but not least, XENON PurePulse technology is available in a wide range of lamps and housings, making it possible to create a system for just about any kind of food packaging challenge and processing environment.

The FDA has issued a call to action, and safety-aware consumers are looking for trustworthy brands more than ever before. XENON PurePulse technology is ready to take on the challenge. To learn more about Pulsed Light and food safety, contact XENON today.