R&D Solutions

Research PE Sintering of Conductive Inks Using Pulsed Light

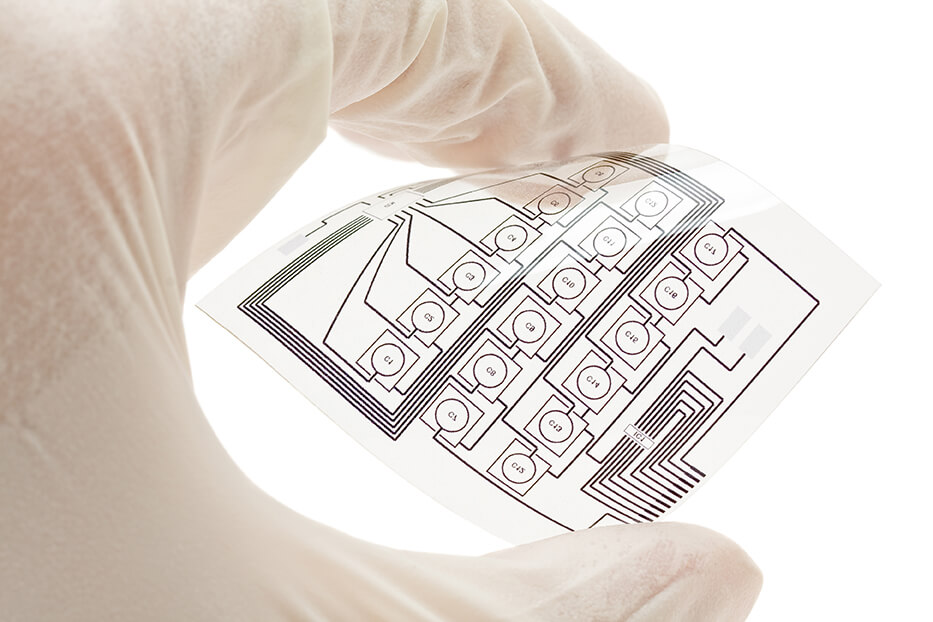

To successfully sinter metallic inks requires precise control of variables within a defined process window to insure proper sintering without substrate damage. Pulsed Light meets the process requirements of silver, copper and numerous other metallic inks by delivering a rapid pulse of energy intense enough to sinter. Controlling peak energies, frequencies and how the energy is delivered provides the required thermal management and process control. And Pulsed Light provides a broad spectrum that addresses the variations in nano-particle size where the spectral absorption is size dependent.

Research PE

Sintering

of Conductive

Inks Using

Pulsed Light

To successfully sinter metallic inks requires precise control of variables within a defined process window to insure proper sintering without substrate damage. Pulsed Light meets the process requirements of silver, copper and numerous other metallic inks by delivering a rapid pulse of energy intense enough to sinter. Controlling peak energies, frequencies and how the energy is delivered provides the required thermal management and process control. And Pulsed Light provides a broad spectrum that addresses the variations in nano-particle size where the spectral absorption is size dependent.

XENON Products For PE Sintering Research and Development

- High energy Pulsed Light research system

- Benchtop tool with small footprint

- Plugs into standard outlet

- Low cost

- Easy setup

The X-1100/2 Now available!

Twice the energy of the standard X-1100

The XENON S-2200 provides state-of-the-art thermal management for researchers working with new nano materials on heat sensitive substrates that require rapid sintering, curing or annealing.

- Thermal pulse management

- Individually-configurable high frequency pulsing

- High peak radiant power

- Operator control of settings

- Protocols stored for easy recall and editing

- Customizable exposure conditions

The XENON S-2210 is designed to help develop effective process protocols for a wide range of industrial applications such as curing, semiconductor wafer treatment, sintering, and rapid annealing.

- Max pulse energy output of 18kJ

- Unprecedented control of pulse features

- Large optical footprint

- Uniformity 3%

The XENON CIXL is the low-cost, all-in-one Pulsed Light solution that incorporates a xenon lamp, power supply and cooling fan, all in a stainless steel housing.

- Lowest cost

- Easy to install

- Easy to use

- Operates on 110 volt

- Use alone or daisy chain

- Factory configured pulse width

Illuminating PE Sintering Research

Want to know more about creating conductive circuits with Pulsed Light?