XENON Products

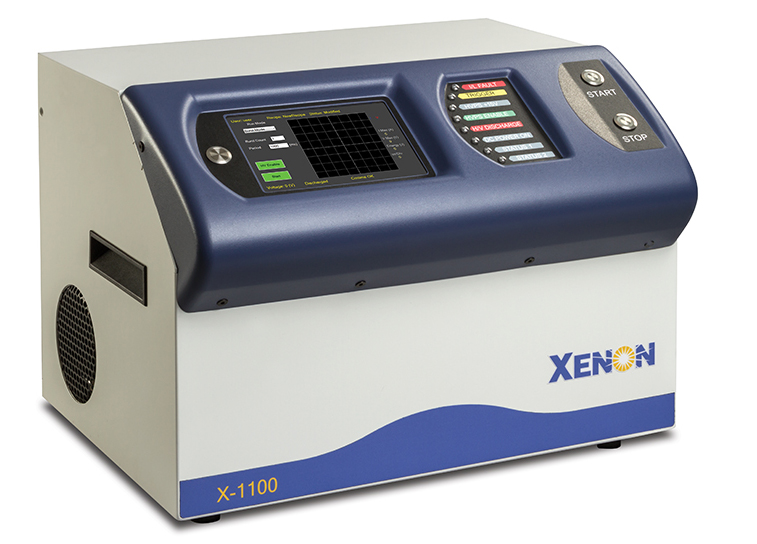

The XENON X-1100

Benchtop Pulsed Light Research System

The XENON X-1100 is the only low-cost benchtop Pulsed Light system that enables researchers to more easily characterize new processes using XENON’s proven technology.

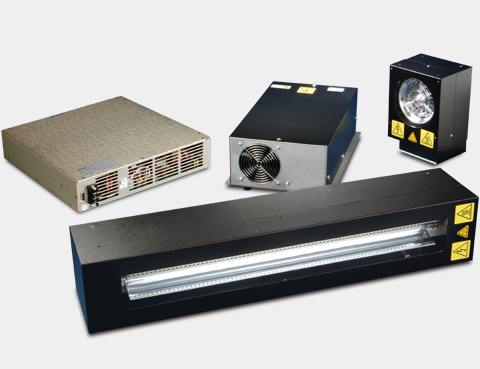

The XENON RC-Series

OEM Systems

The RC-800

Modular Pulsed Light System

Modular system offering single lamp or dual lamp configurations for low heat, fast throughput UV curing.

The RC-900

High Power Modular Pulsed Light System

Modular system offering single lamp or dual lamp configurations for low heat, fast throughput curing.

The XENON CIXL

Compact Integrated Xenon Lamp

XENON’s Compact Integrated Xenon Lamp (CIXL) is the first product that provides everything a user needs to incorporate the power of Pulsed Light technology into its operations.

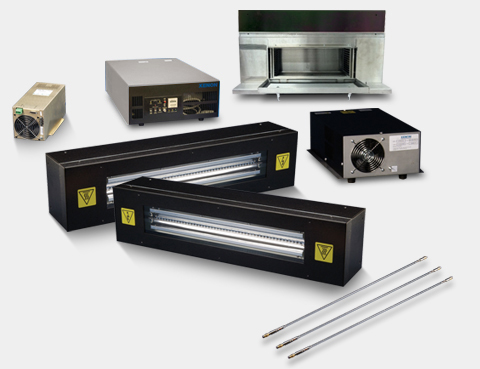

The XENON Z-Series

Disinfection Systems

The Z-1000

Modular Disinfection System

Modular high-speed sterilization solutions for surface microbial decontamination.

The Z-2000

Conveyor Decontamination System

Food-grade controller and wash-down lamp housings designed to meet IP67 and NEMA 4C standards.

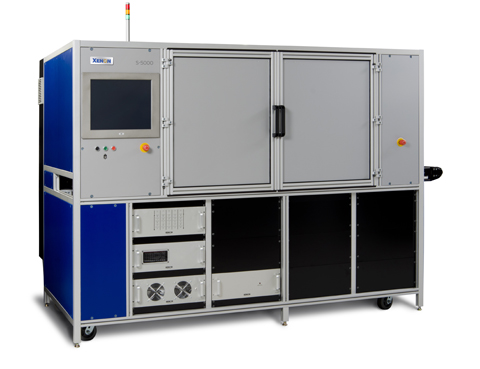

The XENON S-Series

Photonic Sintering Systems

The S-2200

Photonic Sintering Research System

State-of-the-art thermal management for researchers working with new nano materials on heat-sensitive substrates.

The S-2210

Wide Area Photonic Sintering Research System

Compact system is designed to treat wide areas with high uniformity.

The S-5000

Roll-to-Roll Photonic Sintering System

Customizable, multi-lamp system for production sintering at thoughputs of up to 70 feet-per-minute.

The S-5100

Wide Width Photonic Sintering System

Roll-to-roll, high-speed sintering of copper or silver inks on materials up to 50″ wide.